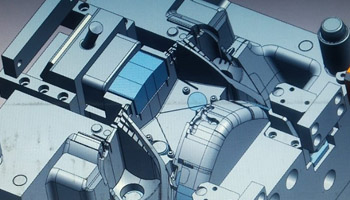

Comprehensive Outline: 3D Metal Printing Process Validation

3D Metal Printing Process Validation 3D metal printing or also known as AM is disrupting companies in aerospace, healthcare, and automotive industries by providing the ability to create intricate and customized metal parts. However, to maintain consistency and quality as well as to be reliable there is need to validate