How To Avoid Flash In Injection Molding?

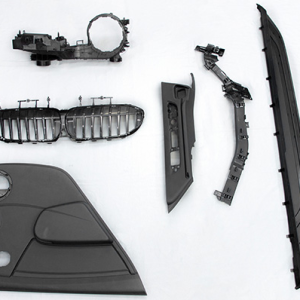

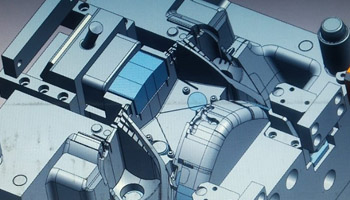

Flash in injection molding refers to excess material that flows outside the intended part cavity, typically along the parting line, ejector pins, or vent areas. Flash can be unsightly and may require additional post-processing to remove, adding to production costs. Here are several strategies to help avoid flash during the