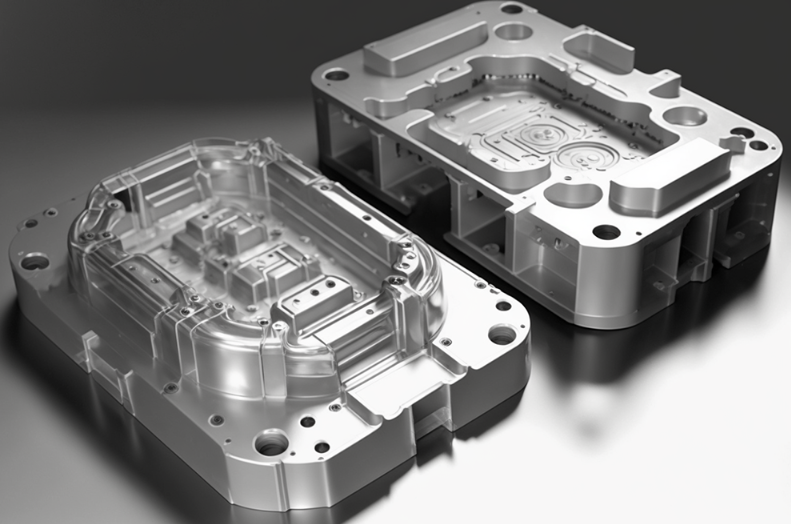

How To Achieve Optimal Validation In Injection Molding?

Achieving optimal validation in injection molding involves ensuring that the molded parts meet all specified requirements and quality standards throughout the production process. Validation ensures that the injection molding process consistently produces parts that conform to design specifications and performance criteria. Here’s a detailed guide on how to achieve optimal